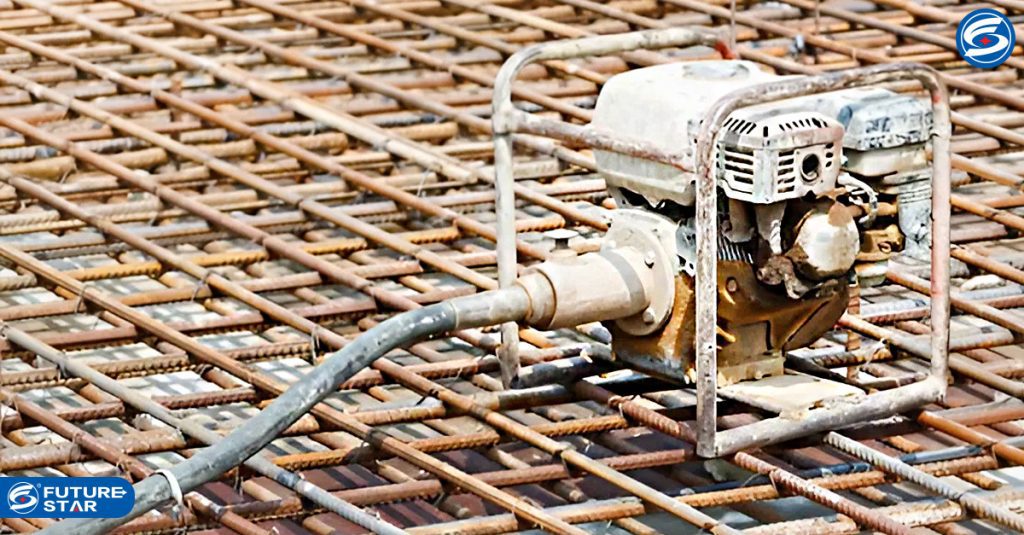

The vibrator machine is placed in the project area where the concrete will be poured.

The position of the vibrator tube is not too far away when pouring.

Quoting from a journal Research Progress of Vibratory concrete Technology. There was an accident in the project work around the wharf in Wuhu, China due to illegal operations in the process of pouring concrete that had an extraordinary thickness.

Then there was a sudden vibration, which caused the cantilever section to collapse. (an extensive arrangement of beams with free ends, prominent and hanging) collapsed while the concrete was being poured and vibrated, resulting in two deaths.

Due to poor vibration of concrete during the pouring process, voids form. And these cavities can jeopardize the safety of workers. For this reason, it is very important that vibrators with vibration technology are designed following the latest developments in engineering applications.

The world of Construction Machinery and Equipment still uses traditional vibrating technology combined with manual experience to provide concrete quality when in a vibrating situation and is very subjective and not well standardized. In the construction industry work will certainly require a person or engineer who can make or design a building mapping that refers to the basis of civil engineering. This is very important, because it will affect the overall quality of construction on concrete buildings.

The number of problems that arise suddenly when doing construction work that utilizes mostly human machines, such as the vibration process. Currently, there are many problems in the vibrating process in the industry, such as External vibrators, also known as surface vibrators, are attached directly to the outside of the concrete form. These vibrators work by vibrating the concrete mixture through the form.

Although external vibrators are limited in the types of forms that can be used, they produce a better surface appearance. The nature of vibration in the concrete process is that it always relies on the experience of the operators at work. Whether or not it is effective must of course be adjusted by whether there is an effective supervision method for the specifications to make the vibration also adjust.

In addition, traditional vibration in construction has many shortcomings, resulting in a decrease in the mechanical quality of concrete, which causes microscopic and structural defects. So it will be increasingly difficult to make concrete with a more effective and compact vibration method with artificial subjective judgment, and the vibration effect is lost.

Rheology The study of the flow of matter, especially when in a liquid state, but also solid and semi-solid bodies when the response is plastic flow rather than deformation (such as elastic, plastic, and failure modes). A vibrating construction method that is currently much needed in the construction world.

This is due to the gradual acceleration of the process of engineering intelligence, intelligent automation research with vibration technology (vibrator) in the construction industry such as civil engineering and water conservancy which was initially slow, and difficult to carry out in terms of performance and function.

As for some characters of concrete under vibrating conditions, it should be explained that it has yield stress and elastic adiposity. Referring to the research journal Academic Journal of Science and Technology that yield stress is the minimum stress that must be applied to concrete in order to make the concrete trigger to flow and deform.