The use of a Beveling Machine is to adjust the slope, that is, on the surface of a beveled edge.

This beveled edge making, has an angle of 45 degrees, but may vary depending on the specific application.

What is the Function of Beveling Cutting Machine?

The use of a Beveling Machine is to adjust the slope, namely on the surface / beveled edge of the material that is not perpendicular to the others.

This beveled edge creation, has an angle of 45 degrees, but can vary depending on the specific application. Beveling is common in a variety of industries, including metalworking, woodworking, glass cutting, and even in medical equipment.

Beveling Process is said to be a very important process in engineering and manufacturing. This is because it involves determining beveled edges, a common design feature found on objects in almost all industries.

Beveling Process

How do you start the beveling process? Beveling can be done easily if you have prepared the necessary equipment and materials. Some steps that must be done before the Bevel process, are as follows below:

Material Selection in Beveling

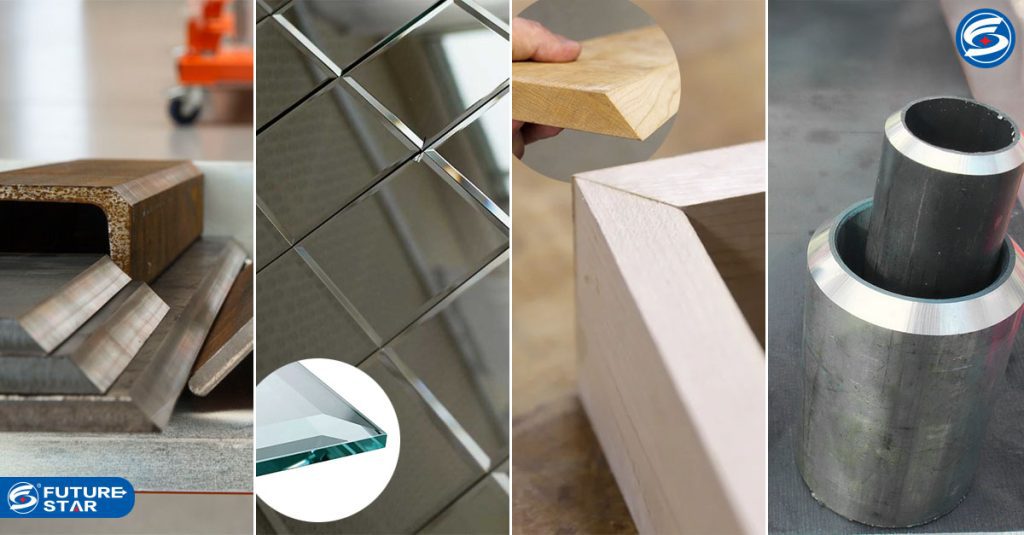

The first step is to select the material that needs to be reveled. Common materials include metal, wood, glass, and plastic.

- a. You need to mark the bevel, on the area to be beveled, you need to mark first using a scraper or marker to ensure precision. This is very important, especially for complicated bevels such as V or X bevels.

b. Bevel Cutting, Work that can be done with manual equipment such as filing, chiseling, and sawing can use a small size bevel machine. Especially in woodworking and metalworking.

c. Power tools, used for bevel work that has greater or more precision. This equipment can cut harder materials and provide consistent angles.

d. CNC MachineIn industrial rules, CNC machines are often used to make more accurate bevels, especially for complex shapes or large production runs.

e. Bevel Finishing, After the bevel is cut, the edges are often smoothed and finished to remove burrs or rough areas. This can be done by sanding, polishing, or grinding, depending on the material.

f. Inspection, The final Bevel finish will be inspected to ensure it meets the required specifications, in particular the angle and edge smoothness.

Precision is critical, especially in applications such as welding, where slope directly affects joint strength.

Some common jobs that use Beveling machines in various industries. Are as follows below:

a. Welding

Beveling is essential in welding to prepare the edges of metal pieces for the joining process. Bevel work requires better weld penetration and creates a stronger joint, especially in thick materials.

b. Glass Cutting

In glass work, beveling is used to create decorative edges on mirrors, windows and table tops. It enhances visual appeal and adds a level of sophistication to glass products.

c. Woodworking

Beveling in woodworking is often the process of creating smooth edges on furniture, cabinets, and trim. It also helps in joining pieces together at an angle, such as in a construction frame.

d. Pipe and Tube Making

In the production of pipes and tubes, beveling plays a role in ensuring that the ends of the pipes can be welded safely. This is particularly important in industries such as oil and gas, where pipes must withstand high pressure.

e. Architectural Design

Bevels are used in architectural design to create clean, angled edges on building materials such as stone, metal, and wood. It is not only for aesthetic purposes but also for functional design elements.