In the screw compressor type, the rotor is the main component and is very important for the operation of the screw compressor. In a screw compressor, the rotor will actively rotate, which then attracts the fluid, then compresses the air. The rotation of the rotor in this screw compressor serves to minimize the available volume while rotating.

In theory, a rotor will effectively increase the pressure on the fluid by using centrifugal force. Therefore, a rotor has the main function of being able to compress the air in the compressor.

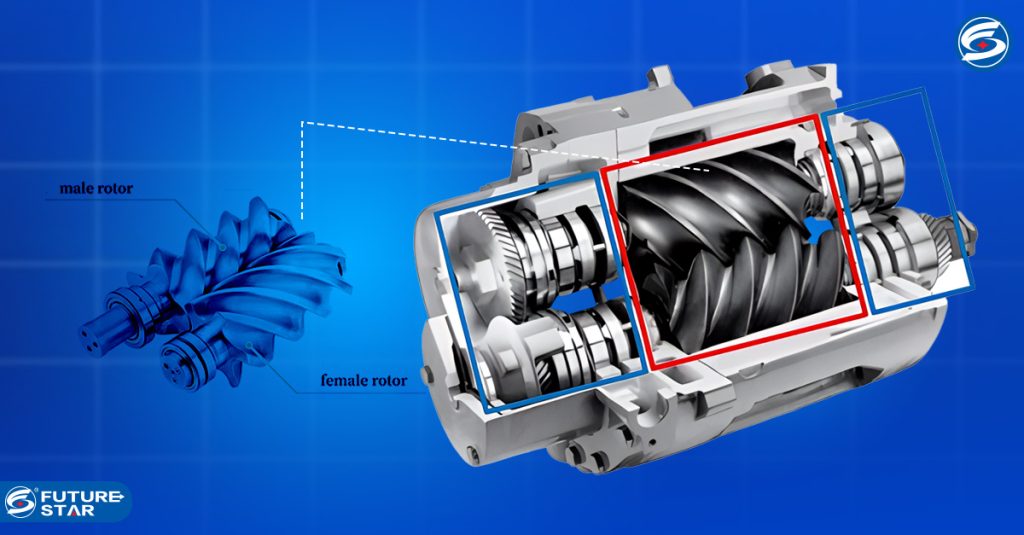

A Screw Compressor will feature a pair of interlocking helically lobed rotors. These rotors rotate inside a fixed casing that encloses them completely. This is the basic principle of a screw compressor.

The space between the two successive lobes of each rotor and the surrounding sheath forms a separate working space with a fixed cross-sectional area. The length of this space varies as rotation progresses, and this occurs due to the displacement of the contact line between the two rotors.

As the rotor rotates, there is a working space that reaches its maximum size when the entire length between the lobes is unobstructed by meshing contacts with other rotors. This is the time when the compressor can maximize its efficiency and performance. However, there is also a time when the size of this working space reaches a minimum value, i.e. zero, at the time of full meshing contact between the two rotors at the end face.

The name Rotor is very popular, because it is a very important part in a world of machinery, including compressors. The function of the rotor is as a transmitter of mechanical power from one component to another.

Without rotors, many machines that we use on a daily basis would not be able to function properly. Rotors also interact with magnetic fields. This is one of the basic concepts in physics that allows rotors to generate motion or even electrical power. An example of this can be seen in electric generators. In it, the rotor spins and creates a magnetic field that ultimately generates electricity.

In the automotive world, rotors also have a very crucial function. This is so that the brakes can stop the vehicle. Without a good rotor, the brakes will not work optimally and this is certainly very dangerous.

So in conclusion the role of the rotor is not only the rotating part of the machine, it is also a key component in many technological applications that we use every day. From power plants to motor vehicles, it can be used in almost any manufacturing industry.

Screw compressors are one type of compressor that is very efficient. Such as gas cooling and compression processes. With a simple yet effective design, these compressors are able to provide consistent and reliable performance.