The use of machinery is one part of the process of running the manufacturing industry which will involve various material and other equipment.

In construction work that we know and know that in the process will always be related to the world of carpentry and heavy equipment, where anyone who approaches the subject must be extra careful.

Make sure you understand and apply Occupational Health and Safety in operating industrial machinery in the field. Some things that you must pay attention to, are as follows:

- Do not place the machine or workpiece on top of the Power Cord. Damage to the cord and current leakage will occur.

- Pay attention to your finger position when lowering the Die Head to avoid pinching your finger.

- Do not leave the machine with long workpieces on it, you may fall and get hurt.

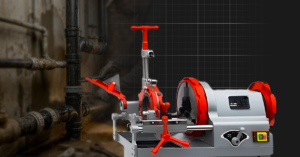

Thread Pipe Machine or commonly called a pipe senai machine is one of the machines that is often used in construction work with pipe involvement as a basic material. This Thread Machine is used when you are repairing pipes or installing new pipes, which allows you to add threads or threads to damaged pipes or cut threads at the end of new pipes.

If you plan to do a lot of pipe threading or own a plumbing business, there are also handheld electric threaders and threading machines that you can use. However, these types of automatic threaders are very expensive and impractical for simple home use when threaded ratchet pipe affordable can get the job done well.

You will need this thread machine or pipe senai machine to do piping project work. This machine is designed automatically, so you can easily and practically use it.

Some examples of pipe work that uses thread machines are as follows: The process of tightening threaded fastener assemblies, especially for critical bolted connections, involves controlling the input torque and turning angle to achieve the desired result of proper preload on the bolt assembly.

Pipe Thread Machine Future Star MODEL Z1T-R2/ Z1/3T-R4 II, The purpose is to make thread or thread formation on the pipe. In addition, this machine can rotate materials such as pipes and rods to cut or thread. This machine consists of a motor that rotates a pipe and a rod, a Scroll and Hummer Chuck to hold the job, Cutter to cut the work, Die-Head to thread the work, and a pump to lubricate the thread oil.

In detail, the conclusion of the function of the Thread Machine or Pipe Senai Machine is as follows: Threading, Thread Cutting and Thread Rolling:

- a. Commonly referred to as Machining with External Diameter (shaft)

- b. Tapping: Thread Machining on Internal Diameter (hole)

- c. Has Size: Note up to 10" shaft

- d. Used for making Straight Threads: Threads on cylindrical surfaces, e.g. fasteners

- e. Used to make conical threads: Threads on conical surfaces, e.g. pipe joints

Thread Rolling Method- small and standard parts, ductile materials Thread Cutting, Thread grinding.

- Commonly used thread applications are to bind

- Special thread application: to transmit motion, to transmit power, to measure, to connect pipes, etc.