We must be more detailed to recheck the condition and structure of iron and steel as the basis of the building foundation.

Rust can occur on iron and steel materials that are affected by air.

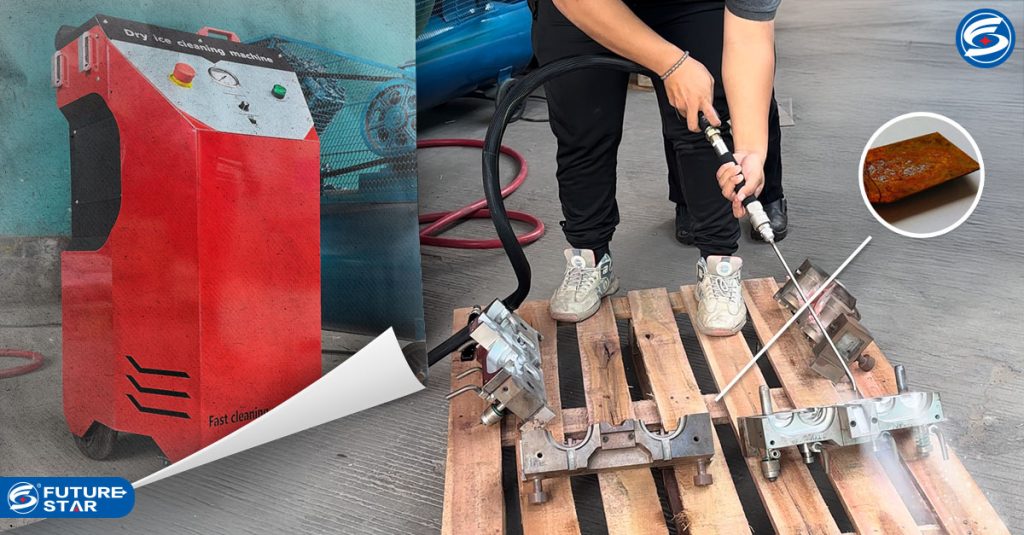

Rust on iron and steel or metal is formed due to the oxidation process. This oxidation process is formed by the presence of water, water vapor and atmospheric humidity. When preparing a construction project, we must be more detailed to recheck the condition and structure of iron and steel as the basis for the building foundation. In construction work, it is common to find super high-rise iron and steel structures exposed to the work environment for a long time. This is because the construction project work itself takes a long time to complete. As a result, many items or tools and construction materials accumulate for too long. So that it triggers rust on everything that has iron and steel material. In Chemistry, Rust is usually referred to as iron oxidation, Iron oxides feature as ferrous (Fe(II)) or ferric (Fe(III)) or both) or more. In the oxidation process, the iron will change color to red when exposed to water or air. This color change event is a mass of iron and steel whenever and wherever the iron and steel will rust exposed to water and air for a long time. Thus causing the iron and steel to be brittle. This is an important problem for construction workers. They certainly have to manage machines and heavy equipment in the work environment (especially manufacturing plants and construction work environments). At the time of setting up the industrial machinery is too old, due to the continuous interaction by chemicals such as dyes, acids, bases and bleaching agents and polluted waste water. On corroded iron surfaces. This will affect the quality and performance of the material as a structural support for the building. Therefore, measures are needed to prevent and clean rust on iron and steel materials. Such as performing rust removal methods by means of rust removal methods, such as grinding, requires a large amount of manual work. In the process of uneven and incomplete rust removal, it will cause damage to the substrate. (the chemicals that are subject to modification). As the development of the times has triggered sophisticated technology in all fields of industry, such as construction. So traditional rust removal methods have been replaced with laser rust removal technology. By utilizing this technology, workers will have more advantages in flexibility and accuracy. The most important thing is to reduce maintenance time and increase the service life of structural section steel. One of the machines with the latest technology developed and can help you in your work. Especially the cleaning and rust removal of structural iron is the Machine DRY ICE BLASTING or Future Star's DRY ICE CLEANING MACHINE P7X.