The mixing methodology for determining concrete quality is often referred to as mixer efficiency measurement.

The mixer efficiency parameter is influenced by the order in which the various constituents concrete fed into the mixer, type of mixer, and mixing energy.

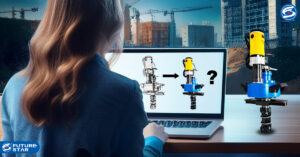

Mixer Molen or stirrer for mixing cement and will continue to be needed in all work, especially in the field of construction involving heavy equipment. One of them is Molen Mixer A cement that is often used to mix or blend various materials used in the chemical, pharmaceutical, plastic, food, and mineral industries.

If we often see a lot of development projects in Indonesia, this indicates that the economic market in the contribution of international trade is still in a standard and good condition. The amount of development will trigger higher and tighter international trade. Export Import is one of the biggest forces of a country as foreign exchange that will never stop.

As well as not all materials, one of which is concrete, have the same structure. So this will affect the condition of the building. And all materials, the performance of the concrete will be determined by one of them is the microstructure. While this microstructure is determined by its composition, curing conditions, and also the mixing method and mixer conditions used to process concrete. The mixing procedure includes the type of mixer, the order in which the materials are fed into the mixer, and the mixing energy (duration and power).

In Indonesia itself, we certainly find many types of construction equipment and machines that have a large capacity of buildings, such as the construction of large apartments, buildings, public institutions, etc., so the existence of a Molen Mixer is needed to expedite the work. However, for smaller construction projects, such as the construction of simple housing, shopping centers, or housing construction, tools and machines are still rarely used, because in general they still rely on manual labor (humans) to mix cement with sand so that the cement mixer process is used with the capacity of the molen machine mixer barrel on the market ranging from 125 liters to 500 liters.