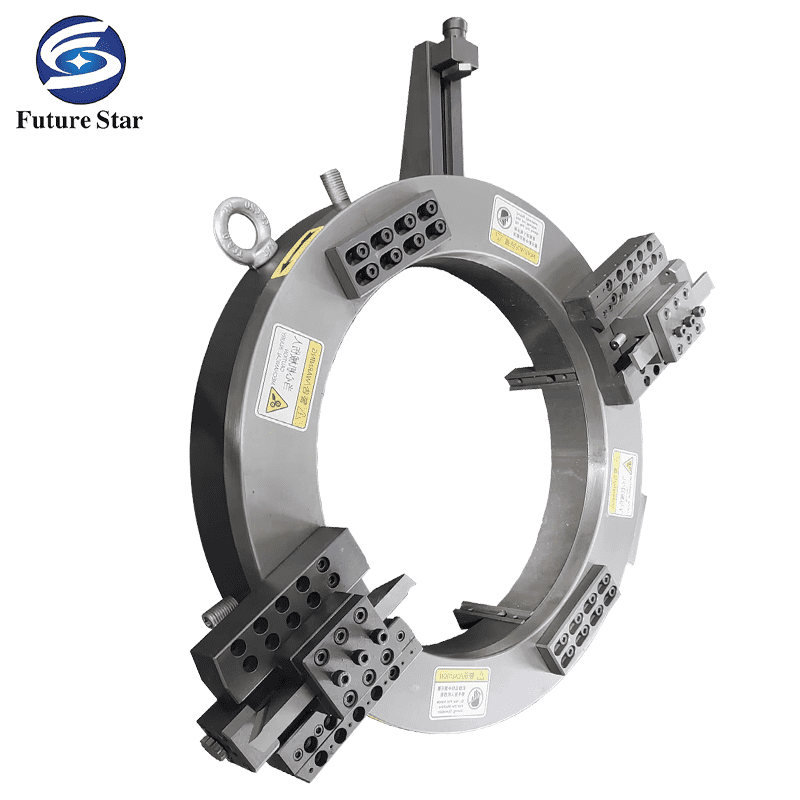

Model: GPD-325

Pipe O.D(mm): 180 - 325 mm (6-12″)

Wall Thickness (mm): 3-25

N.W(KG): 80

G.W(KG): 115

Dimension(mm): 700*700*260

GPD-219 PIPE CUT AND BEVEL MACHINE

Specifications

Outlet diameter 80-219mm

Wall Thickness 3 - 25mm

GPD-168 PIPE CUT AND BEVEL MACHINE

Specifications

Outlet diameter 60 - 168mm

Wall Thickness 3 - 25mm

Pneumatics

Air Pressure: 0.6 - 1.5mpa

Air Flux: 1500-2000L/min

Application

The portable design can realize indoor and outdoor grooving work as long as there is a source.

Suitable for pipe beveling before welding materials include ordinary steel, stainless steel, nonferrous metals, hard plastics, etc. Widely used in power plants, shipyards, petroleum and chemical industries, dealing with pipeline construction, maintenance and maintenance work. Through constant improvement, the product can not only replace the traditional beveling mode by gas cutting and polishing, improve work efficiency, reduce labor intensity, but also can improve welding quality.

Function

Simple installation and quick operation. It is applicable to various kinds of material processing, and available for various pipe diameters. Because it adopts mechanical cutting groove method for cold cutting, it can keep the mechanical properties of material quality well. And it can also do flat-end, V, X, U shape slope to the pipe. Thus, it can meet all the requirements for butt welding.

Features

1. Split frame design

2. High-performance electric drive

3. Fire resistant, lower noise level

4. Strong strength and stable rotation

5. Cut and tilt simultaneously

6. Automatic feeding, completing fast feeding and knife pulling operations. Easy and fast operation, self-installed in the pipe center

7. High beveling speed and labor saving