Offshore drilling work, is one of the mining jobs whose process takes a long time in producing something that is the goal of the drillers. Some examples of work in the field of petroleum and coal or gold drilling. Therefore, this work is quite heavy and has many risks when workers are in the location area.

Drilling speed is greatly influenced by the rock properties and performance parameters of the drillers. By conducting theoretical analysis, we can predict the ideal drilling speed based on the characteristics of the rock to be drilled. This is not only a theory, but also a practice that can be applied in the design of drilling machines.

By understanding the direct relationship between drilling speed and rock properties, we can get more accurate calculation results. This is especially important for manufacturers looking to design efficient drilling machine parameters.

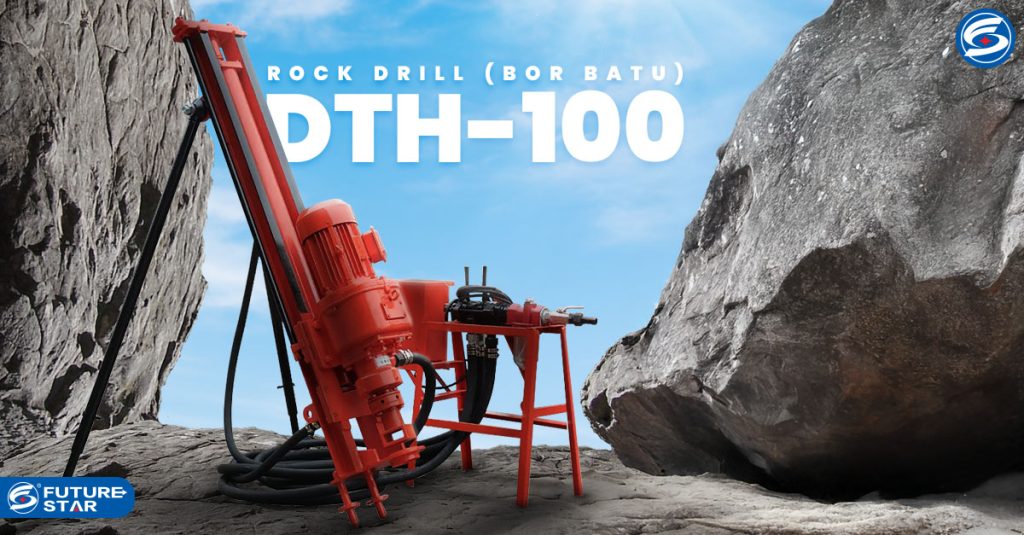

This method of using Rock Drill is predicted to have speed in drilling techniques. Such as crushing or breaking by rotating based on theory. As for the comprehensive effects that must be considered, such as the prediction of drilling speed. Meanwhile, the method of determining and testing drilling parameters by crushing will have solid rock indicators as illustrated. As a technological innovation of high-power hydraulic rock drill, the double damping system has a very important effect on impact performance. The double damping system is a floating mechanism. The characteristics of the floating mechanism have an important influence on the impact energy, frequency and power of the hydraulic rock drill.

Thus, Rock Drill manufacturers can use the parameter design of the drilling machine. And users can choose the most suitable drilling machine, which can greatly reduce the workload of prototype manufacturing and testing. The correct use of Rock Drill is the most essential and important subject in drilling practice.

Rock Drill (Drilling Machine) is a function for drilling work on holes that are in the ground. There are several functions of Rock Drill in several jobs such as prospecting, sinking wells (petroleum, natural gas, water, and salt), and scientific exploration. Drilling holes in rock to receive blasting charges is an operation in tunneling, mining, and other excavations.

Rock drillability is a comprehensive index that indicates the ease of drilling holes in rock masses. It is also the ultimate basis for drill bit design, optimization of drilling operational parameters, and penetration rate prediction.

Rotary drilling can be used in some mining jobs for making every corner underground. In most rotary drilling, the hollow steel rod has a place to circulate cooling water or other fluids.

Source: Wang Hong, et al. (2017). Study on Prediction of Rotary-Impact Drilling Speed of Rock Drill. International Conference on Manufacturing Engineering and Intelligent Materials, Pg.201: Vol.100

Han Yannong. ( 2020). A new approach to evaluate rock drillability of polycrystalline diamond compact bits using scratch test data. Energy Exploration & Exploitation, Pg.885: Vol.38 (4)