Rotary Screw Compressors function not much different from other types of compressors

These compressors also help in positive energy transfer. Rotary Screw Compressors are most commonly single stage helical or spiral lobe. This type of compressor consists of two rotors inside a casing where the rotors compress the air internally.

Rotary Screw Compressors: Improving Energy Transfer In the world of industrial machinery, rotary screw compressors play an important role in facilitating positive energy transfer. They function similarly to other types of compressors, but with their own unique features and benefits. The most common type of rotary screw compressor is the single-stage helical or spiral lobe compressor. In this article, we will delve deeper into the functions and advantages of the Rotary Screw Compressors,

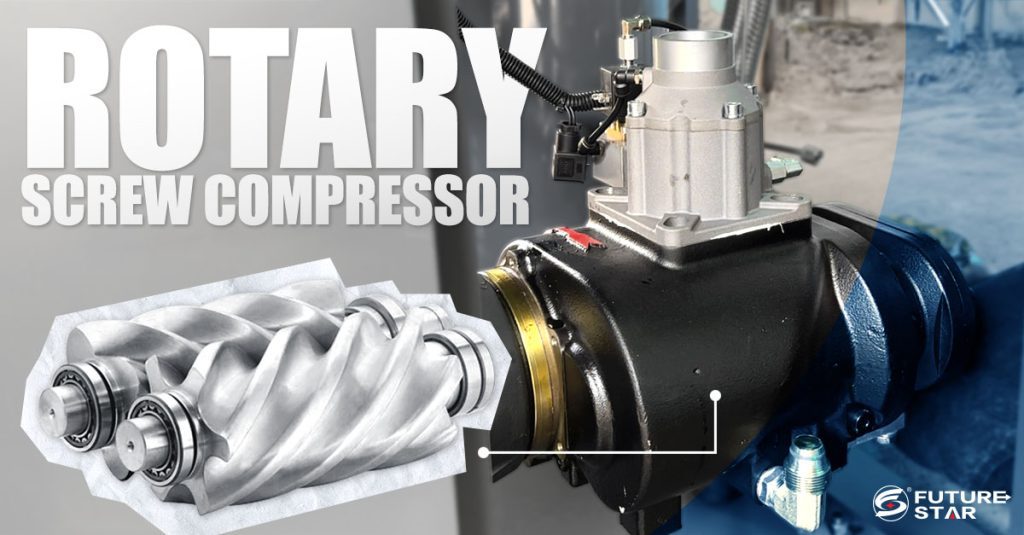

Specifically focusing on the internal compression process and the role of the rotor. How Do Rotary Screw Compressors Work? Rotary Screw Compressors function by utilizing two rotors encased in a casing. As the rotors rotate, they compress the air internally, resulting in high-pressure air that can be used for a variety of industrial applications.

The unique design of Rotary Screw Compressors enables continuous and smooth operation, providing a reliable source of compressed air for manufacturing processes, automotive equipment, and other equipment that requires compressed air.

What Makes Rotary Screw Compressors Different from reciprocating compressors that use pistons to compress air. Rotary screw compressors operate in a rotary motion resulting in a more efficient and silent compression process.

Importance of Rotor Design in Rotary Screw Compressors? Rotary efficiency and performance depend heavily on the design and quality of the rotors. The two rotors inside a compressor are precisely designed to create a sealing compression chamber that traps and compresses air as it moves through the system. The tight clearance between rotor ensures minimal leakage, allowing for maximum compression efficiency and consistent high-pressure air output.