But the fact is that not everything will work out for the better. Increasingly, the world will experience fossil fuel depletion, which will certainly affect fuel prices.

Human intervention as the main processor of natural resources will affect the reaction of nature to humans themselves. As is currently the case with the depletion of fossil fuels in the form of decaying plant and animal remains.

But the fact is that not everything will work out for the better. Increasingly, the world will experience fossil fuel depletion, which will certainly affect fuel prices.

Therefore, researchers continue to develop their science and knowledge, so that they can produce a solution to replace these fossil fuel energy sources. Now many researchers have found other sources of energy.

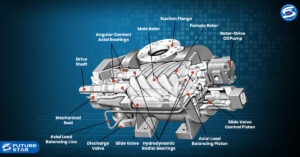

An Air Engine from a Compressor is a type of engine that uses compressed air technology to produce useful work output. The function of this machine is to store pressurized air in the tank. This pressurized air will enter the tank has great energy, so the piston engine will move.

Compressors are pneumatic machines that have lower pressure using a compressed air system (CAS). Compressors are widely used in various industries, such as manufacturing, mining, road transportation, railways, marine and aviation. In addition, pneumatic tools, medical equipment, blow off technology, cleaning, and cooling, etc.

Because the transmitted compressed air must meet the capacity with the quality requirements of consumer demand. Make sure the operational process of the pneumatic device is correct. Improper selection of CAS can lead to increased energy costs, cause equipment failure, reduce production efficiency, and increase maintenance requirements.

Some of the energy will be lost due to CAS inefficiencies, both pressure and leakage, and including other constraints. When the compressor loses energy in CAS can be categorized into 3, namely: loss due to waste, artificial demand, and energy so that it cannot be used according to its function.

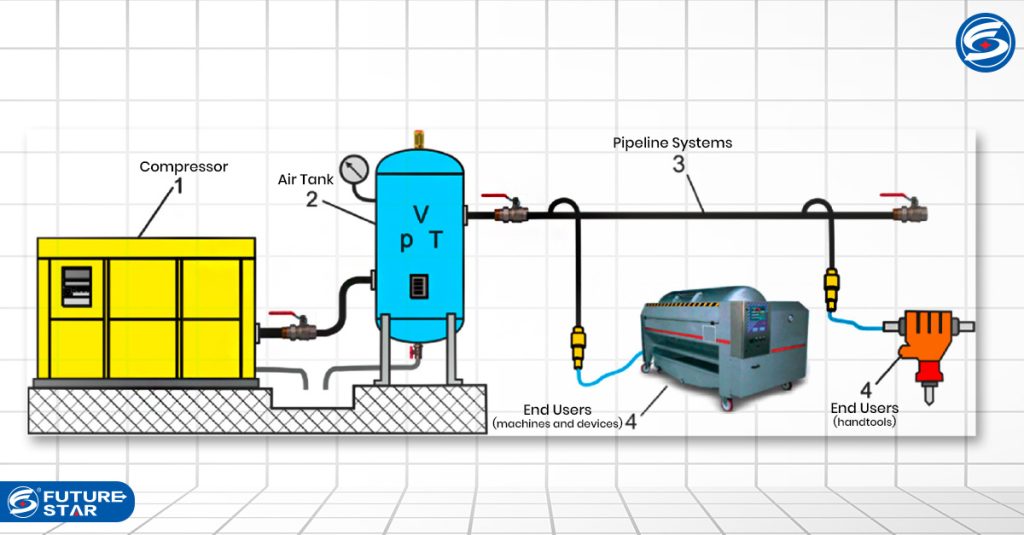

Industrial CAS consists of three main parts: compressed air production plant (compressor, compressed air tank, drying, filter, regulating system), compressed air pipeline, and compressed air consumer. To receive, store and deliver compressed air, CAS uses a compressed air receiver tank (CART). It is also called an air compressor tank, compressed air tank, compressed air receiver, or compressed air storage tank.

Here are the benefits if you make savings by using energy in CAS, including:

- Reduced electricity consumption for compressor drive, improved compressor efficiency (16% energy saving).

- Reduce energy loss in CAS by reducing air leakage and pressure loss (energy savings of 18% energy savings).

- Improve the efficiency of pneumatic control, using the new energy saving control method (2% energy saving).

- Reducing energy demand costs and reducing operating time reduces pressure operation (it is difficult to estimate energy savings).