The continuous development of the technological era is now able to engineer geotechnics at the highest point with technology grouting machine.

Advancements in this technology are developing very fast and significantly with the patenting of more innovative methods.

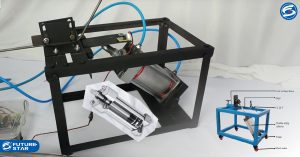

In the Manufacturing Machinery Industry, the reliability and strength of production machinery is a major factor that is very important for the smooth running of construction projects. This also has a direct impact on the benefits of an industry's facilities. Some of the majority of construction machinery and other heavy equipment certainly have related functions and uses in working on a project. As in machines that function as rotating or reciprocating rotation, in piping, or as auxiliary systems, equipment installation, grouting, anchoring, and frames or foundations. All of them will certainly have a constructive relationship in shaping strength in the long run. Grouting is an advanced method nowadays that is widely used to reinforce and seal rock, soil and concrete. The possibility to seal structures is very important from an economic and environmental point of view. The cost of grouting on certain projects can be as high as the cost of blasting and tunneling. To improve grouting techniques with cement-based materials, it is necessary to examine the properties of the grout mixture used. Grout is an integrated component of the equipment system that forms a monolithic contact between the equipment and the building frame. So that it can be distributed to make effective load, energy dissipation, and damping. The important role of grout itself is especially as epoxy grout (basic components or cured end products of epoxy resins), when the equipment is working, the reliability of the equipment, and the cost is not too high. Electric Pump Grouting is used for a compaction process that is based on how soil treatment techniques involve the injection of cementitious grout in the soil with a thick consistency under pressure into the mass of the soil, so as to increase the density of the surrounding soil. The pressure in Pump Grouting, will be transmitted through the grout with low mobility, which can produce compaction by displacing the soil at depth until it is retained by the weight of the overlying soil. Grouting Compaction is achieved by injecting into very dense soils or at the very base of the rock. Grout compaction will have some limitations, due to the presence of dense surrounding material.