Inverter compressors are a type of compressor that is superior in the energy efficiency category compared to other normal compressors. By matching motor speed and actual air requirements, inverter compressors prevent the energy waste that is directly related to constant cycling and idle operation. Precise control enables significant energy savings, thereby reducing electricity costs and reducing the impact on the environment. This is also an important reason why inverter air compressors are increasingly used in industry and production.

Inverter Compressor Industry

The compressor is one of the machines that is always mandatory in every manufacturing industry, especially in the construction, oil and gas sectors, where every operational activity will require lots of large machines to facilitate the operators’ work. The compressor industry generally includes several equipment that can be used in air conditioning, including air compressors which are the main choice for inverter air compressors.

Reciprocating Inverter Air Compressor

Reciprocating inverter air compressors or also known as piston inverter air compressors are a type that we often encounter and are usually used in various industries. In this type of compressor, the operational mechanism of the system uses a piston movement system to compress the air. This compressor also functions to provide efficient and precise control of air flow and pressure, making it suitable for various applications that require varying air requirements.

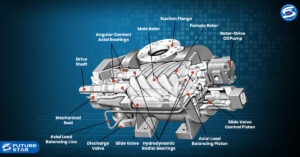

Centrifugal Inverter Air Compressor

A centrifugal inverter air compressor is a compressor that has dynamic properties that uses centrifugal force to compress air. This compressor uses a rotating impeller to accelerate and compress air and is capable of producing high pressure output. Apart from that, centrifugal compressors have high efficiency and reliability, so they are ideal for large-scale industrial applications that require continuous pressurized air and require high volumes.

Scroll Inverter Air Compressor

Scroll Inverter Air Compressor is a compressor that in its operation uses two spiral-shaped coils that lock together and compress the air. This compressor has a design that is compatible with extraordinary energy efficiency and requires simpler maintenance.

Not only that, this type of compressor has flexibility so it is the most popular and much sought after in various industries that prioritize oil-free and clean compressed air, including pharmaceutical manufacturing, electronics and food processing.

This type of compressor is an ideal choice in industries that prioritize air quality in controlling contaminated air.

Screw Inverter Air Compressor

Screw inverter air compressors are widely used in industrial environments and are one of the compressors that are very reliable and have high efficiency. This type of compressor can operate by using two pairs of intermeshing screws which compress the air when rotating. Screw compressors are also able to accommodate a continuous supply of pressurized air so they are suitable for work applications that require high volumes and varying air requirements.

KOCU Pneumatic Grease Pump High Quality Standard

Grease Pump merupakan mesin industri manual yang digunakan untuk mengoperasikan, memelihara, dan mentransfer oli dengan viskositas tinggi pada tekanan konstan. Cocok juga untuk digunakan sebagai