Understanding the Reciprocating Air Compressor Reciprocating air compressors are amongst the various models of compressors that are capable of transferring positive energy from the engine. This occurs when the engine is in operation and increases the air pressure by decreasing its volume. As a result, some air becomes trapped in a closed space, providing a higher air pressure. The piston in the cylinder plays a crucial role in compressing and transferring the air pressure as a single or double stage.

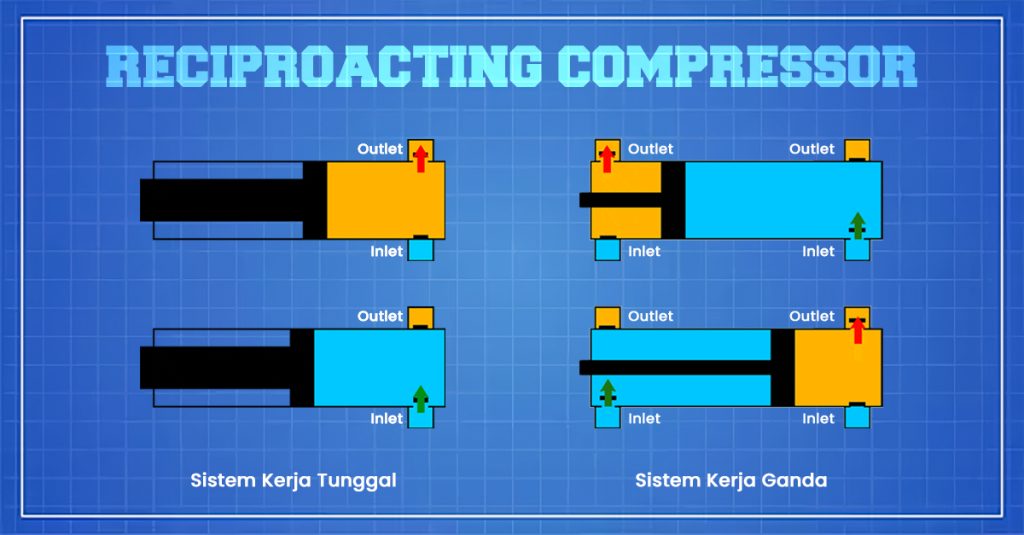

- The Main Stages of Reciprocating Air Compressors Single Stage:

- The entire compression process is completed with one cylinder or a group of cylinders in parallel. Generally used for pressures ranging from 70 psig to 100 psig.

- Two-Stage: Two or more compression stages are grouped in series. Commonly used for pressures ranging from 100 psig to 250 psig.

Single Action: Compression is carried out using only one side of the piston.

Double Action: Utilizes both sides of the piston. By understanding these different stages, users can choose the appropriate reciprocating air compressor based on their specific needs and requirements.

Advantages of Reciprocating Air Compressors Reciprocating air compressors offer several advantages, making them a popular choice for various applications. These advantages include:

- 1. Versatility: Reciprocating air compressors can be used for a wide range of applications, from small workshops to large industrial settings.

- 2. Durability: With proper maintenance, reciprocating air compressors can last for many years, providing reliable performance.

- 3. Cost-Effectiveness: Compared to other types of compressors, reciprocating air compressors are often more affordable, making them a cost-effective choice for many businesses.

- 4. High Efficiency: Reciprocating air compressors are known for their high efficiency, ensuring optimal performance and energy savings.

- 5. Wide Pressure Range: The ability to operate at different pressure ranges makes reciprocating air compressors versatile and adaptable to various applications. In conclusion, reciprocating air compressors offer a reliable and cost-effective solution for individuals and businesses requiring compressed air for their operations. By understanding the different stages and advantages of reciprocating air compressors, users can make an informed decision when selecting the right compressor for their needs. Whether it’s for a small workshop or a large industrial setting, reciprocating air compressors are a versatile and efficient choice.